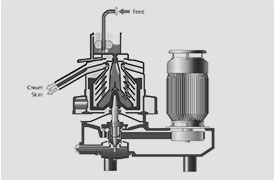

Centrifuged Latex

ALLEPPEY LATEX

Alleppey Latex (P) Ltd produces a wide range of rubber based products. The following are the major products.

Centrifuged latex (60% DRC)

The company produces Centrifuged Latex. It is mainly used for producing mattress, condoms, gloves and all type of rubber products. The machinery used for centrifuged latex is Alfa level centrifuges mantufactured in Sweden.

Creamed latex (52% DRC)

The Company produces creamed latex, which is mainly used by companies manufacturing mattress, rubberized coir, balloon and adhesives.

At Alleppey Latex Pvt Ltd, we specialize in high-quality Creep Rubber products, designed to meet diverse industrial and agricultural needs. Our Creep Rubber, processed through meticulous latex centrifugation, is known for its superior elasticity, durability, and consistency. We ensure that our products adhere to the highest standards of quality, sustainability, and safety, making them ideal for a variety of applications, including footwear, adhesives, mattresses, and other rubber-based products.